Tool/software:

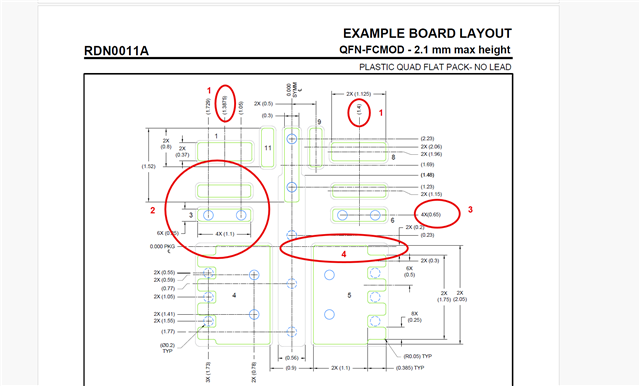

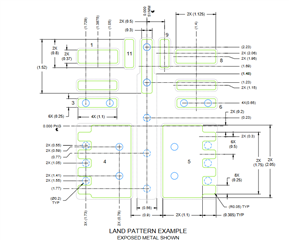

I'm trying to make a layout symbol for TPSM365 but have some questions about the recommended footprint.

What does the gray and green indicating?

I can’t understand how we should make metal and mask for pin10(GND).

Also, I found the Ultra Librarian for this IC.(link below)

Is the above NSMD as recommended in datasheet?