Tool/software:

Hi Team,

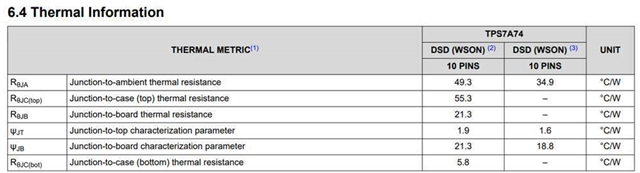

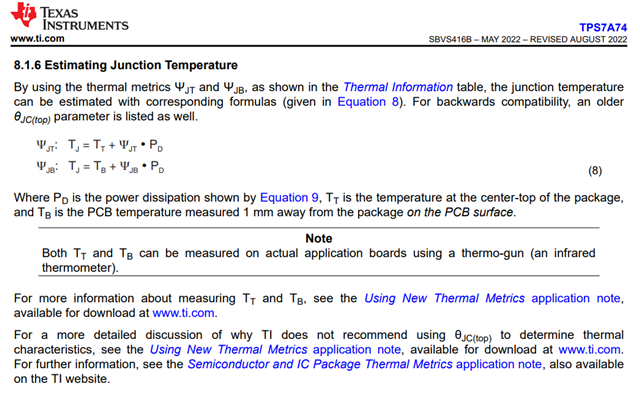

The customer reported that the measured case temperature of TPS7A74 is 90℃. If RθJC(top)=55.3℃/W is used, the junction temperature is about 124℃. Is this expected? In addition, can you share a guide, including how to test the case temperature, etc. Thanks.

Regards,

Hailiang