Tool/software:

Hello Experts,

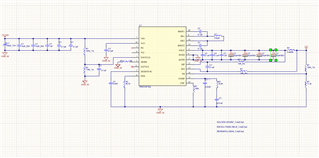

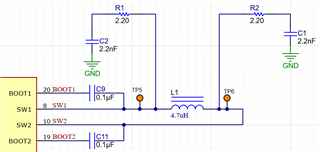

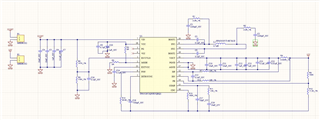

I am going to use TPS552872Q IC as my Buck Boost Converter in my BMS project, following are the preset values:

Input Voltage Range = 09 - 32V

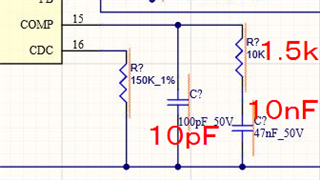

Output Fixed voltage = 12V

Max Output Current = 2A

Switching Frequency = 300kHz

Efficiency = 98%

Enable voltage = above 1.2V

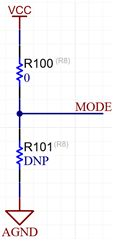

In Auto PFM mode

Kindly verify the Schematics and let me know