Tool/software:

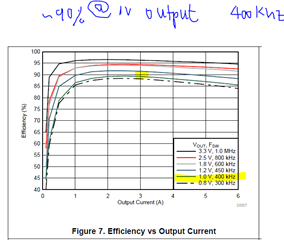

I am working with a DC-DC TPSM84624MOLR. Input voltage 12V and an output voltage 1V.

I ran the test on evaluation board TPSM84624EVM-013.

according to the datasheet, the expected efficiency is ~85%, but I'm only achieving 79% in my setup. I didn't change anything in EVB.

Is this efficiency drop acceptable, or does it indicate an issue with my design/setup/components?

What factors could be causing this lower efficiency, and what steps can I take to improve it?