Other Parts Discussed in Thread: BQ25622

Tool/software:

I am using the BQ25622E for an application with 12V input (nominal), single Li-ion output so 3.5V-4.2V output, and 1A charge current approx.

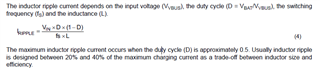

I have come to choose the buck circuit inductor using Equation 4 in the datasheet:

Nominal

Re-arrange Eq4 for L, assume 30% ripple of 1A output, and nominal input/output voltages;

D = V_BAT / V_BUS = 4V / 12V = 0.3333

L = VIN * D * (1 - D) / (fs * I_RIPPLE) = 12 * 0.3333 * 0.6666 / (1.5MHz * 0.3A) = 5.92uH

Worst Case

Re-arrange Eq4 for L, assume 20% ripple of 1A output, and worst case input/output voltages;

D = V_BAT / V_BUS = 4.2 / 18V = 0.2333

L = VIN * D * (1 - D) / (fs * I_RIPPLE) = 18 * 0.2333 * 0.7666 / (1.5MHz * 0.2A) = 10.73uH

Both of these are huge compared to the typical application circuit given in the datasheet, and the EVM circuit design which both use 1uH.

However both of those sources say they support the ranges I use (listed as up to 18V for input) so on one hand I should be able to just copy the same circuit and use the 1uH inductor size but viewing from another direction this should be 10x larger!

So a couple things;

- Even accounting for this calculation being 1A charge current instead of the full 3A charge current, this still gives 2uH, so a 2.2uH part would be chosen. This is still a way away from the 1uH in the EVM and datasheet calculations - this is still only at 12V, before accounting for these circuits saying they are for use up to 18V at the input. Is there a mistake in the typical/EVM circuit (e.g. actually designed for 5V input only would make sense), or is there no mistake but just that it is OK for it to be stretched away from the ideal at other input/charge conditions?

- Do I follow the calculation, or go with the typical circuit? The typical circuit should also cover my usage conditions but yet gives a hugely different inductor size to the calculation.

Thanks for any help

Kevin