Other Parts Discussed in Thread: GPCCHEM,

Tool/software:

Hi,

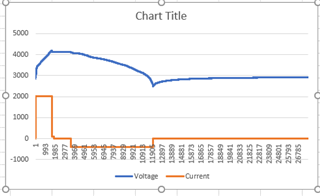

Following a long conversation in forum with one of TI guys, we proceeded with doing the chemID test again and got a new chemID (2153) and started doing learning cycles on the BQ34Z100 using our pack. As mentioned in every other post, we made sure our pack was discharged to empty, let to rest for > 5 hours, IT Enable and RESET were given, charged to full. But update status never goes to 05. But one of the guys from TI said even though update status didnt go to 05 our learning cycle was completed (idk what basis they said that). I'm attaching the logs. I hope someone can help us complete this learning cycle, it drained every bit of energy left in us and we've spent so much on the board to stop this now. Old thread: e2e.ti.com/.../bq34z100-g1-dodateoc-dod0-qmax-dod0-stays-at-0

Thanks in advance,

Srinath

1184.DataFlash_afterchg_25-6.gg.csv