Tool/software:

Hi,

How to choose peak-to-peak inductor current ripple if I have more than working condition which have quite different output current like 1A and 10A?

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tool/software:

Hi,

How to choose peak-to-peak inductor current ripple if I have more than working condition which have quite different output current like 1A and 10A?

Hello Zehui,

Thanks for reaching out to us.

If you are calculating the inductance value based on inductor ripple current, always use the maximum output current.

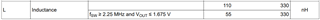

For the case of TPS62873-Q1, the inductance range is already pre-defined (see table below). If the priority is to have a fast transient response, then choose a lower inductance value in the table. A possible drawback is higher ripple current and output voltage. To achieve a lower ripple voltage, consider a higher inductance but expect a slower transient response (potentially higher overshoot and undershoot).

Best regards,

Excel

Hi Excel,

There is a problem when using larger output current, a smaller inductor value will be calculated by the formula. When working at a smaller output current, the ripple current is much larger than the common recommendation of 30%. Will it be ok?

Yes, thank for mentioning that. I also see there is a list of recommended inductors. So let's not focus on the specific device and talk about the usual BUCK application.

Hi Zehui,

Thanks for the quick feedback.

Can you provide an actual use case of your concern using a larger output current / smaller inductance and smaller output current / high ripple current? It's unclear for me.

Best regards,

Excel

Hi Excel,

ILPP = VOUT×(VIN – VOUT) / VIN× L × fsw

If you use the formula above, you can see if the Iout is larger, which means the recommended ILPP(peak-to-peak inductor current) is larger if you choose 30% of Iout as ILPP, so the inductor you need is smaller after calculating.

If Iout is 10A , assuming the calculated result is 1uH. Then with Iout =1A, L=10uH. That is quite different.

Hi Zehui,

I understood your point. But the items you highlighted is expected. To achieve a low ILPP, it requires higher inductance, and a low inductance will result to higher ILPP. Anyway, using the minimum load current in calculating for the inductance value it is too conservative and will require an inductor with very high DCR (inductor DC resistance) which leads to lower efficiency. In addition, a low ripple current is not recommended in some control scheme because it could lead to loop instability because it's susceptible to noise and poor transient response.

For TPS62873-Q1, the recommended effective inductance is between 55nH to 330nH because the control circuit is optimize to work on this range only.

I hope I was able to address your queries.

Best regards,

Excel