Tool/software:

Hello TI team,

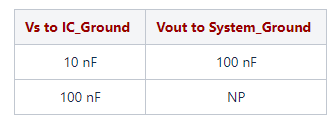

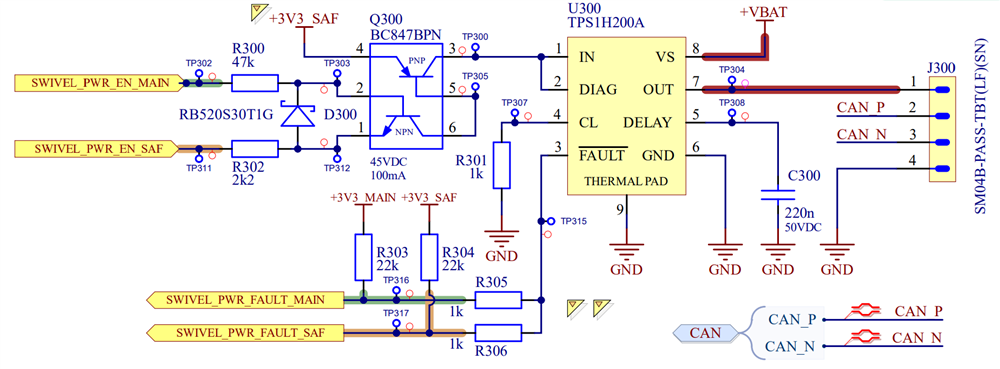

I am wondering if you could assist in an issue we've been having with the TPS1H200AQDGNRQ1 smart high-side switch. We have been using this part in our designs for a while but during a recent implementation on a new board we've encountered an issue. First of all, here is the schematic:

Top layer layout, it's a 4-layer board

For clarification, on this system we use two MCU's (in the schematics they are differentiated by MAIN / SAF in the label) that both can control the IN pin of the TPS1H200A, likewise they can both read the status of the FAULT pin. This is due to the fact that our system will be certified against the 61508 functional safety standard. To enable (close) the switch, SWIVEL_PWR_EN_MAIN must go HIGH while SWIVEL_PWR_EN_SAF must go LOW. As you can see, a current limit setting and a shut-off delay are also implemented.

All of this is functioning correctly. However, we have now had two instances where the IC blows up upon connecting the batteries to the system (the batteries are directly connected the the VS pin via the +VBAT net label), this does not always happen but when it does (2 times now) the resulting damage is the same, see below.

At the moment when we connect the batteries and the damage occurs, there is no load on the OUT pin since we have not connected any cable to J300. At first I expected a one-time (soldering) mistake, but since it has now happened twice I am wondering if something else is wrong.

Do you perhaps see any improvements to due design? Let me know if there is any further information you need.

Thank you!

Maarten