Tool/software:

Hi team,

I have one issue and three questions around BQ76952 that need your support.

Issue summary:

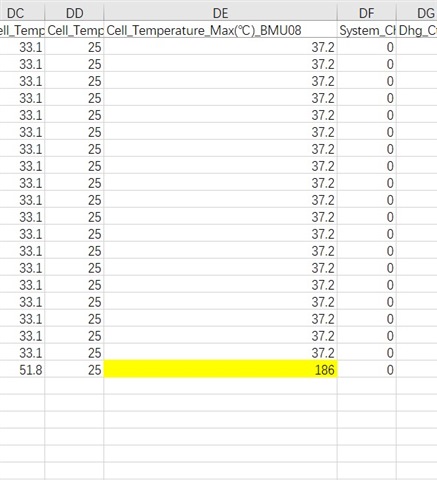

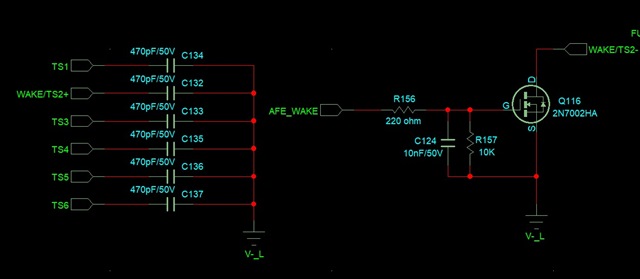

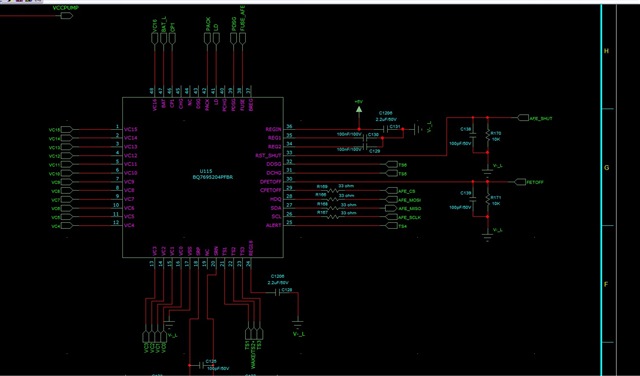

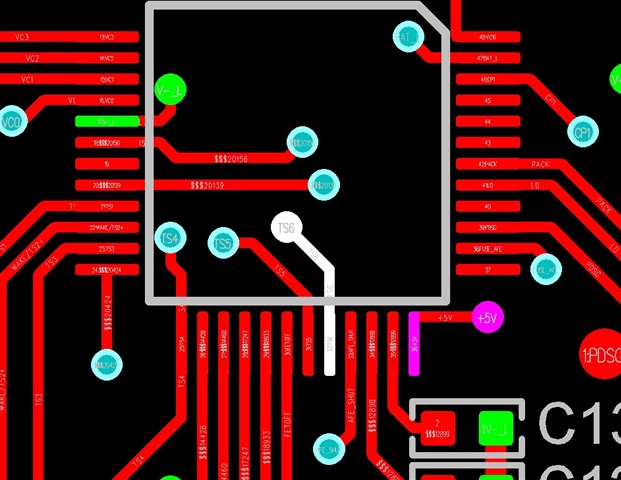

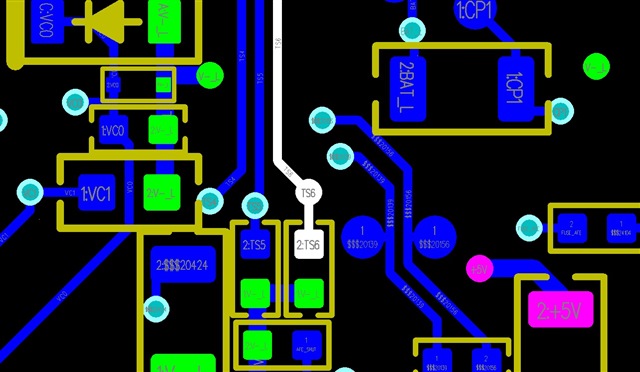

When using BQ76952 to read the cell temperature through TS1/2/3/4/5/6, the temperature will jump from 30 to 168, which is abnormal as the temperature should be a parameter change continuously. Could you please help to check the root cause or give some debug direction? The sch and PCB is as below. (Pin 31,32,25,21,22,23 are connected to thermistor to sense the temperature of each cell) The filter capacitor (470pF) of TS4/5/6 is set on another layer in PCB board. There are 2 assumptions: (1) The internal register is abnormal, but we don’t know the potential reason, customer implement CRC check in software; (2) There are noise on input signal. But there are 470pF capacitor series in the input signal path.

Support need:

Help to check the root cause and provide the debug direction.

Questions:

1.Do we have the common issue summary or user guide of BQ76952 to help customer minimize their potential design risk in application? Except help to review the sch, what can we support?

2.Do we have the example of software register set-up recommendation for customer’s reference?

3.For the cell balancing timing: When the cell is measured, the balance for this cell will be disabled. Does this only work for auto cell balance by BQ76952 itself or also work for MCU control cell balance?

- If it only works for Auto cell balancing, customer should turn off the cell that is being measured by MCU. Right? If the sample time is 100ms, how to ensure the time delay between MCU send command and cell disabled? Customer said they found this time delay is about 1s, which is too long.

Thanks!

BRs,

Rannie