Other Parts Discussed in Thread: GPCCHEM, GPCRB

Tool/software:

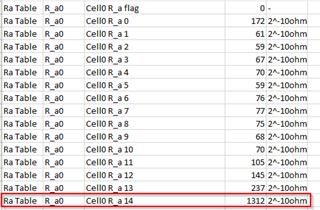

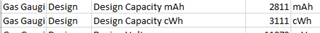

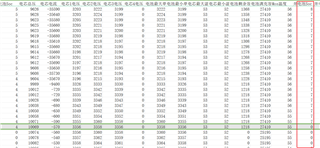

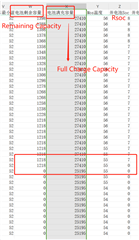

BQ4050-R1 full load test discharge to SOC 7%, turn off the load and stop discharging, SOC delay for a few seconds, then jump to 0; What is the reason for SOC jumping to 0 when the recorded voltage data does not reach the zero jump voltage? What conditions can cause SOC to suddenly jump to 0?

Please check the attached images in these two columns.

Please check the attached images in these two columns.