Tool/software:

Hello E2E Support,

These questions apply to a critical long duration space flight mission.

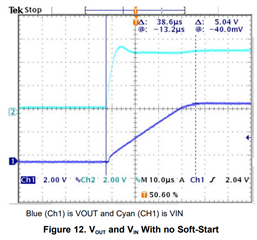

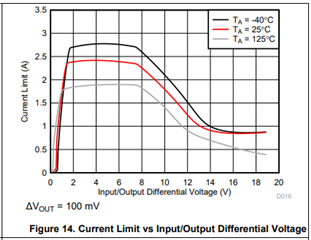

The TPS7A4501-SP (Flight Prt Num: 5962R1222403VXC) does not have a soft start feature, consequently when enabled with stable Vin, Iout appears to go to the maximum current limit (~2.3A simulated, which is in excess of the recommended 1.5A max operating current) and stay there until the load capacitance is fully charged, at a rate and duration determined by:

Ic=C[dV/dT], see simulation waveforms attached.

For this application Vin=5V, Vout=3.3V, Cout=(150uF + 22uF + 1uF), see schematic attached.

Questions:

1.) Is this expected behavior or am I mistaken?

a.) If mistaken, please explain how/why.

b.) If not mistaken and this is expected behavior:

i.) Can the TPS7A4501-SP/5962R1222403VXC sustain driving out its maximum current limit indefinitely without degradation to reliability and/or performance?

ii.) If no, is there a specified time limit for which the part can sustain driving out its maximum current limit without degradation to reliability and/or performance?

iii.) In any event, for a critical long duration space flight mission is it advisable to implement a soft start feature for the TPS7A4501-SP/5962R1222403VX, e.g. what’s done on the evaluation board? Our PCB is real-estate constrained so implementing the soft-start might not be “low-hanging-fruit” …

Thank you, -John