Other Parts Discussed in Thread: TPS73801-SEP,

Tool/software:

Hello,

My customer was considering TPS73801-SEP for their design. Their requirements are as follows.

Vout = 0.7V to 3.3V

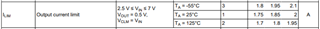

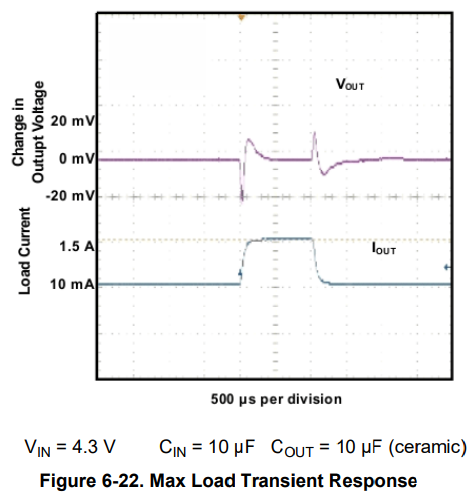

Iout = <1A

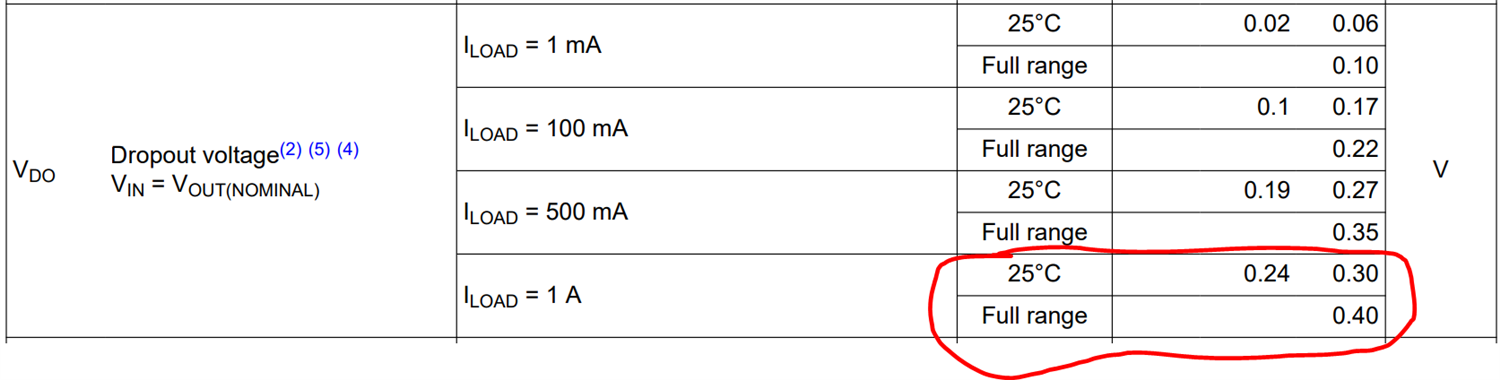

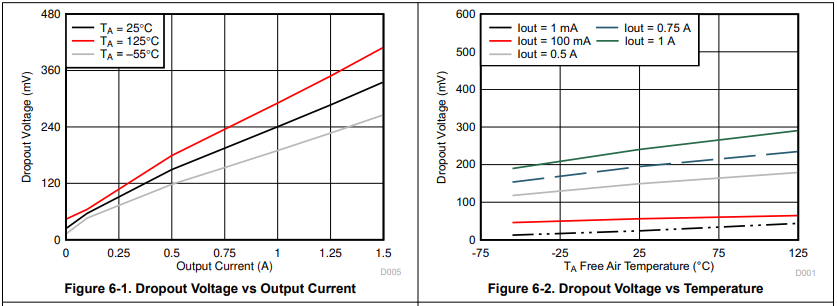

Vin – Vout = <0.5V

Ta = -45oC to +85oC

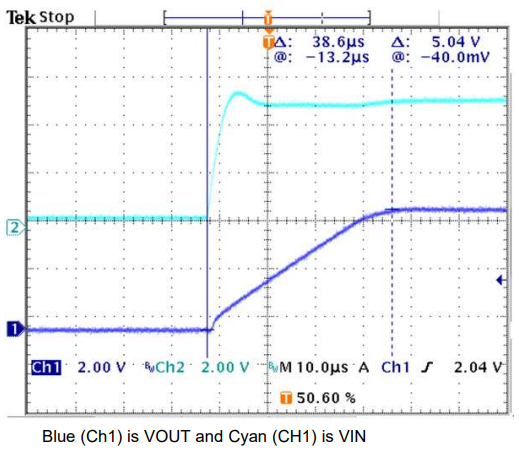

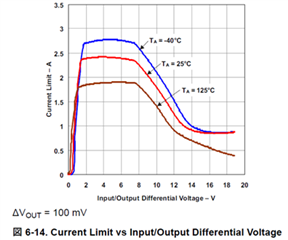

Looking at Figure 6.4 of the TPS73801-SEP datasheet, they are concerned if they could really use TPS73801-SEP at Vin – Vout < 0.5V without triggering the current limit.

So they also started considering TPS7H1111-SEP instead. However, the TPS7H1111-SEP datasheet does not have plots like the Figure 6.4 of the TPS73801-SEP datasheet. Does TI have plots for Current Limit vs Input/Output Differential Voltage depending on temperature for TPS7H1111-SEP?

Best regards,

K.Hirano