Other Parts Discussed in Thread: BQ27531-G1, BQ24192

Tool/software:

We are using bq27531evm in our application with a single-cell battery, here is the specifications of the battery:

1.Battery Specification

1.1 Product Specification

|

Description |

Specification |

|

|

Typical Capacity |

3500mAh |

|

|

Minimum Capacity |

3400mAh |

|

|

Shipment voltage |

3.8~3.95 V |

|

|

Nominal Voltage |

3.7V |

|

|

Fully charge voltage(FC) |

4.2V |

|

|

Fully discharge voltage(FD) |

3.0V |

|

|

Charge Voltage |

4.2±0.03V |

|

|

Standard Charge Method |

0.2C CC (constant current) charge to FC Voltage, then CV (constant voltage) charge till charge current decline to 0.01C |

|

|

Standard Discharge Method |

Using 0.2C constant current discharge to FD Voltage |

|

|

Max. Charge Current |

0.2C |

0~15℃ |

|

0.5C |

15~45℃ |

|

|

Max. Discharge Current |

0.2C |

0~70℃ |

|

0.5C |

15~60℃ |

|

|

Inner Impedance |

pack≤120mΩ |

|

|

cell≤50mΩ |

||

|

NTC |

10K±1% 3435K |

|

1.2 PCM Electrical Characteristics

|

Item |

Limit Values |

||

|

Min |

Typical |

Max |

|

|

Overcharge Protection voltage |

4.23V |

4.28V |

4.33V |

|

Over-discharge detection voltage |

2.7V |

2.8V |

2.9V |

|

Discharge over-current detection current |

3A |

/ |

7A |

|

Overcharge detection delay time |

0.8S |

1.0S |

1.4S |

|

Over-discharge detection delay time |

10mS |

/ |

120mS |

|

Short detection delay time |

50uS |

/ |

400uS |

|

Current consumption |

/ |

/ |

8.0uA |

2.Custom Application Requirements

We want to set some custom values in our application:

- set Fully charge voltage to 4.1V;

- set Fully discharge voltage to 3.5V;

- set Max. Charge Current to 1A, 0~60℃; stop charging when temperature rises above 60℃;

- no limit to Max. Discharge Current;

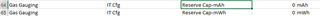

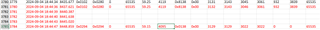

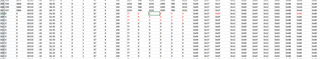

3.Our Data Memory configuration file

After calibration, Chem ID program and cycle learning, here is our configuration file of data memory, please help us check if this configuration file is suitable.

4.Our Data Memory configuration file

Can you give us a configuration file example that mees the custom application requirements.