Tool/software:

Hi TIer

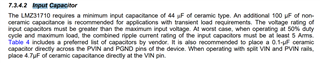

I see there some requirement with Cin in datasheet 7.3.4.2.

I saw this non-ceramic capacitance was suggested to be added to improve the load adjustment rate, but my customer is using sensitive power supply equipment such as DDR, FPGA, etc.,

So can I recommend that the customer use ceramic capacitance paralleling instead of this non-ceramic capacitance. What are the risks?

Why non-ceramic capacitance increases the load adjustment rate?