Tool/software:

Hello,

I am an FAE at a distributor that handles TI products.

I received the following question from my customer.

During EMS (immunity) testing, LEDs may flicker.

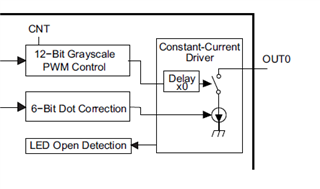

No PWM control. Maximum duty.

Used for brightness control with dot correction only.

As the interference level is increased, certain LEDs begin to flicker, and as the level is increased further, many LEDs flicker.

Since there are differences in resistance to interference depending on the LED port, we suspect that the interference component is being applied to the LED output, not the communication line between the CPU and the LED driver.

(Question)

Could flickering be caused by noise being applied to the constant current circuit?

If so, what measures can be taken?

Would inserting a capacitor between the output port and GND be an effective measure?

Are there any other possible causes for the LED flickering?

Best regards,