Other Parts Discussed in Thread: LM76002

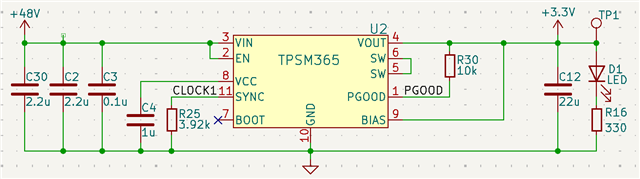

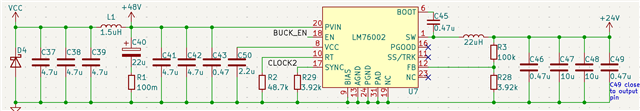

I'm working on a design where a 48V DC source needs to be converted to both 3.3V/0.5A using the TPSM365R6 and 24V/2A using the LM76002. The 3.3V output powers a microcontroller that controls the ENABLE pin of the LM76002, allowing it to save power when the 24V output is not needed. Due to limited board space, I'd like to use a single EMI filter for both buck converters, which I understand would require synchronizing their clock frequencies.

According to the application report "Synchronizing DC/DC Converters in a Power Tree" (Section 1.4 https://www.ti.com/lit/an/slvaeg8/slvaeg8.pdf?ts=1724355001771), it's possible to synchronize the clocks of two buck converters by connecting the switch node voltage of the one converter (in this case, the TPSM365R6 at 3.3V) to the sync pin of the second converter (LM76002). However, the report notes that "Depending on the input and output voltage ratio, the switching waveform can be used directly as a clock reference for the other converter."

Given the significant voltage ratio (48V/3.3V) the expected duty cycle of the TPSM365R6 is 8.25%. I'm unsure if this synchronization strategy will work effectively. Ideally, I'd like to keep the switching frequency around 400-500 kHz for better efficiency.

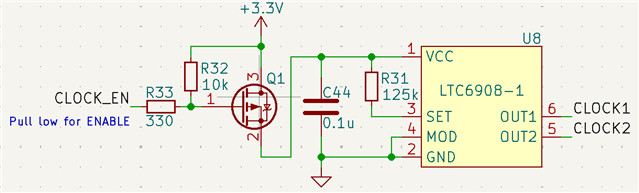

If this approach isn't feasible, I'm open to other suggestions that would allow the use of a single EMI filter. One option might be using an external clock source, powered by the 3.3V output, though this would require additional components. Alternatively, I'm open to considering different buck converters, perhaps those with a clock output pin.

Thank you.