Tool/software:

hello. My name is Myungsu Kim.

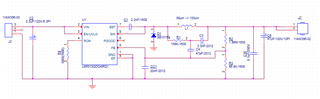

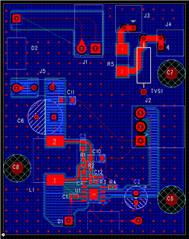

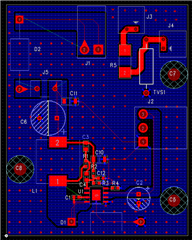

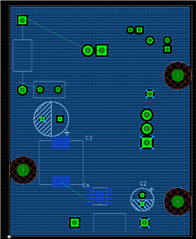

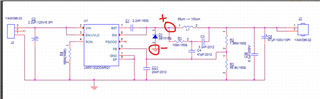

A DC-DC converter circuit was designed using LM5013, using the design tool provided by TI.

The PCB was designed and the components were assembled as samples, and during testing, the LM5013 CHIP was destroyed while applying input voltage to two samples.

One CHIP exploded and one caught fire.

The input/output conditions are,

The input voltage was set to DC76V and the output voltage was DC48V, and the input voltage was supplied by connecting the battery.

The input voltage was supplied using a connector, but it is not clear whether the + voltage was connected first and the - voltage was connected later.

I don't know if this was the cause, but I would like to know what problem could cause this phenomenon.

I am uploading the circuit diagram and CAD data attached.

Please review