Tool/software:

Hello,

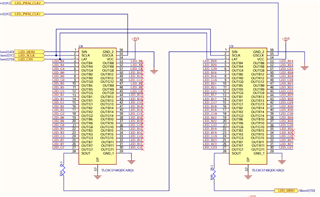

I have been working from the data sheet to create a driver for the TLC6C5748, but the behavior I am seeing does not match what I would expect.

Could I please see your source code example so I can compare and see what I might be doing wrong?

Thank you so much,

-Scott