Tool/software:

Hi,

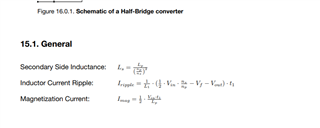

I am using LM5036 for my design conditions

Vin:20-95V, Vout:13V, Iout:30A

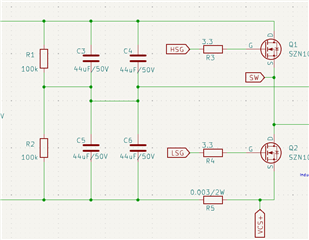

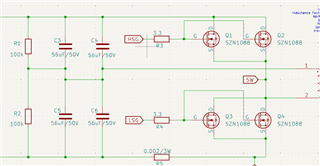

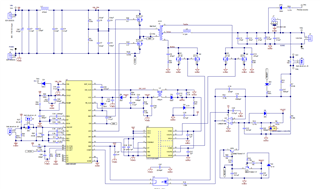

Using LM5036 EVM schematic as reference.

Just had few technical questions regarding the working, etc. I have gone through the datasheet and other technical material, but still some doubts - If you can help explain that will be of great use to me

a. can you share what is the value of Vaux1, Vaux2 and Vx in the EVM schematic?

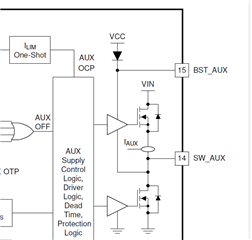

b. Can you help explain the startup operation and then Vcc taking over by AUX supply- my ques is how can AUX supply output Vcc when Vcc itself is needed to power the gate drivers as we can see from functional block diagram? There should be an existing Vcc already for flybuck operation to even start. Please correct me here.

c. Can you also help explain in brief RESET connection which i used in the level shift detection circuit and then connected to D7 and R14.

Thanks a lot,

(I might ask other minor questions over other components used in the schematic as I work on my design going forward so will use this thread to converse with you)

Sahil