Tool/software:

Hi,

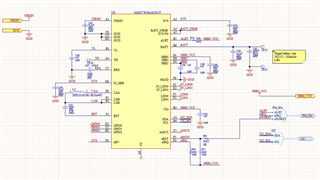

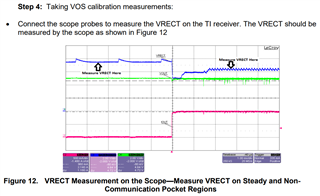

We are using the BQ51003 on two of our new products and we have the same problem on both. I followed the exact same schematic and component values as shown in SLUA748A with component values and coil. We were not able to source the Qi Sniffer from AVID Technologies as it doesn't exist.