Other Parts Discussed in Thread: BQSTUDIO, , BQ25628E, GPCRB

Tool/software:

Hi Team,

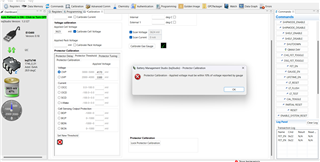

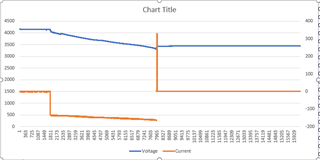

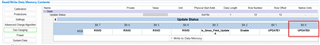

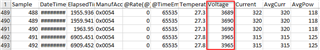

In our project, we are using a LiPo battery, and we need to identify its chemical ID. We are using the BQ27Z746 fuel gauge for monitoring the battery parameters through BQStudio and the BQ25628E as the battery charger. We have attempted to calibrate the fuel gauge using BQStudio and successfully calibrated the cell voltage with the measured cell value. However, we were unable to calibrate the other values according to the hardware design parameters. To identify the chemical ID, we referred to the TI document 'Simple Guide to Chemical ID Selection Tool (GPC) (Rev. A)' and having some doubts in the process ,its mentioned below .Please help us to solve this.

| OVP | 4100 | mV |

| UVP | 3300 | mV |

| OCC | 14 | mV |

| OCD | -16 | mV |

| SCD | -20 | mV |

| I-Wake | -2 | mV |

| BDP | -200 | mV |

| BCP | 200 | mV |

| BDN | -200 | mV |

| BCN | 200 | mV |

Regards,

Nithya