Tool/software:

Hi TI community,

I’m working on an LM5118 design with the following specifications and I’m having a hard time finding a suitable inductor. I’m not that experienced in power electronics and hope someone would like to share their experience.

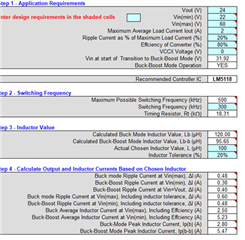

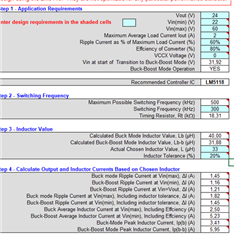

Specification

- Vout = 24V

- Vin = 22V to 60V

- f = 300kHz

- Maximum load current = 2A

- Minimum load current (CCM operation) = 200mA (10% of max load)

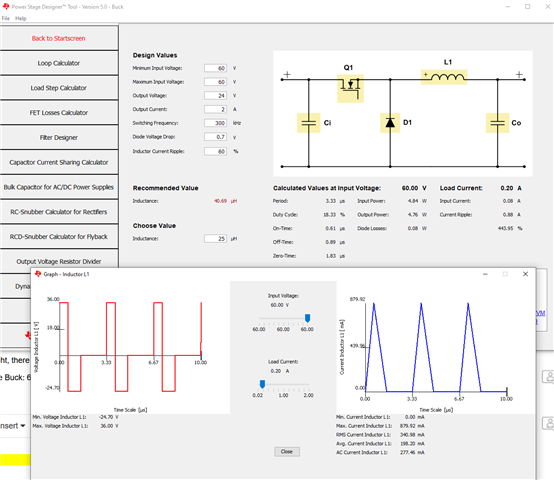

Using the Excel tool (snvu065a) and the datasheet, I find an inductor value of 100uH.

However, the peak current in the inductor is around 5.5A, which is pretty high for an inductor of this size. I’m unable to find a suitable inductor with a saturation current higher than or equal to the peak current of 5.5A. Any suggestions?

Are my design specifications too tight or is there something that I have misunderstood?

The Webench power designer suggests a 33uH inductor. This results in an inductor ripple of 1.45A at worst-case Vin. This will limit the minimum current in CCM to 1.45/2 = 0.725A.

This, from my perspective, is a high current as a minimum, when the maximum load is 2A.

The nominal current of my application is around 200mA. Can the converter operate in DCM at this current? Is it bad design to run in DCM mode? What are the disadvantages of this?

Any advice on inductors, advantages, and disadvantages of the design is appreciated.

Best Regards,

Sam