Tool/software:

Hi,

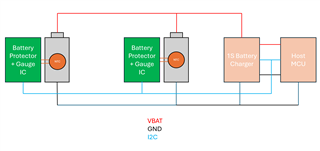

May I get some advise on whether connecting 2 x Lithium Ion Cells in parallel (1S) would be suitable for this device?

How would you go about connecting the 2x NTC thermistors to the TS pins?

The cells are not part of the same pack in my application.

Any further guidance/tutorial on battery charging from TI is kindly appreciated.