Other Parts Discussed in Thread: TPS65126, , TPS6521905

Tool/software:

Hello Team,

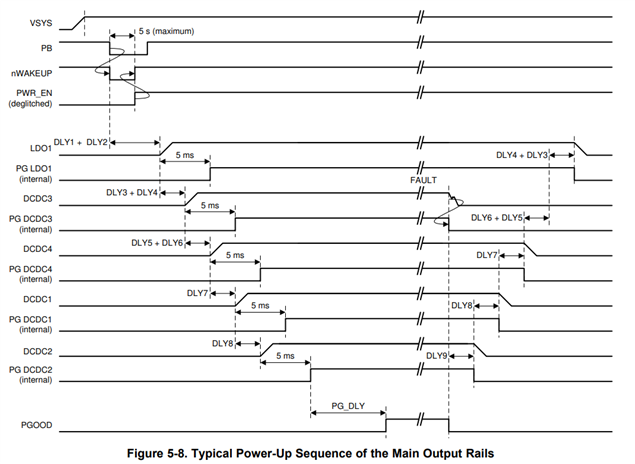

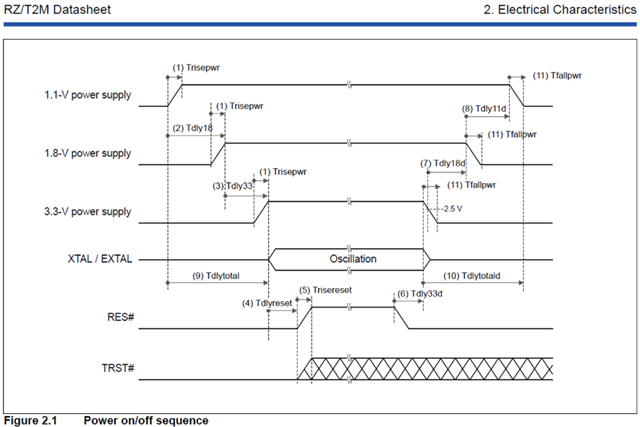

Customer plans to use TPS65126 as a biasing power for Renesas RZT2M with RX65N(Communication chip) devices.

- Power On Sequence : 1.1V -> 1.8V -> 3.3V

- Power OFF Sequence: 3.3V -> 1.8V -> 1.1V

There're two questions here;

1. How does TPS65126 do the i2c programming on register for power sequencer design?

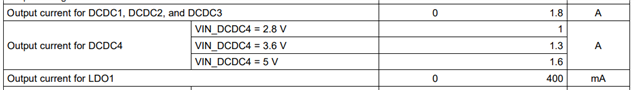

2. Below is a load table of MCU/FPGA/others, the loading currents are under TPS65216's max current. it should be ok, right?

|

Voltage Rail |

TI-28377(Operation Current) |

FPGA(Operation Current) |

RZ/T2M (Max Current) |

RX65N (Max Current) |

Summary Current |

|

|

0.9V |

Not applicable |

80mA |

Not applicable |

Not applicable |

80mA |

|

|

1.1V |

Not applicable |

Not applicable |

660 mA (Core) |

Not applicable |

660mA |

|

|

1.2V |

450mA(Operational Mode) |

Not applicable |

Not applicable |

Not applicable |

450mA |

|

|

1.8V |

Not applicable |

Not applicable |

80mA (I/O) |

Not applicable |

80mA |

|

|

3.3V |

90mA(Operational Mode) |

50mA |

80mA (I/O) |

80 mA |

300mA |

Application: Servo Drive

Regards

Brian