Other Parts Discussed in Thread: BQ25798, TIDA-050047, TPS25751, TPS65988, BQ25756

Tool/software:

Hi TI Team,

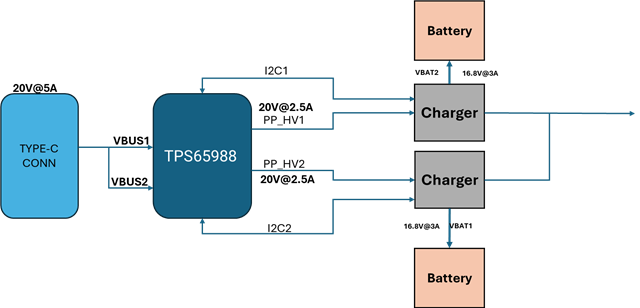

I am working on a Project where i needed Two 4s Batteries to be used based on Higher Load Requirement using Type-C Power.

Can i use TPS25750 as a PD Controller & BQ25798 as Battery Charger for my above Application. As my Battery charges at a Rate of 16.8V @ 3A. Can you please suggest if I can use the following IC's or need to go for any Alternate parts

Block Diagram is attached for your Reference.

Immediate Response would be Highly Appreciable.