Other Parts Discussed in Thread: ISOM8110, LM431

Tool/software:

Hi,

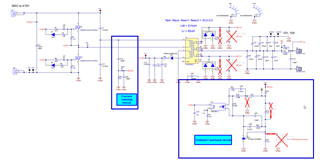

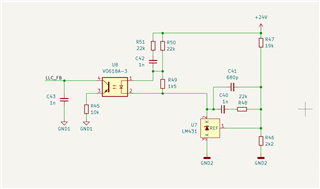

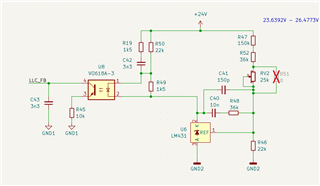

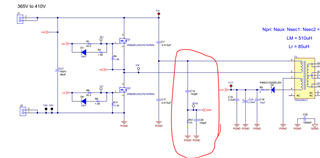

When it comes to the UCC256601 LLC controller i need isolated FB , this is normally done through an optocoupler but i noticed that TI has some optoemulators available.

I was wandering how to design to use them. Also i am not sure how to set the mirrored FB current properly and how it should scale through the optocoupler/optoemulator.

THX in advance