Other Parts Discussed in Thread: LMR51430, LM76005,

Tool/software:

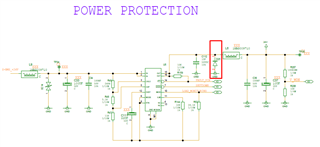

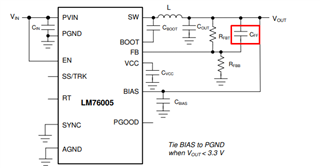

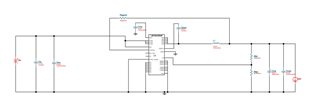

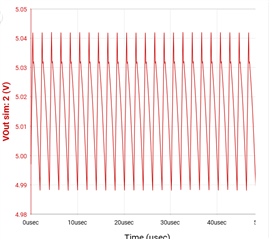

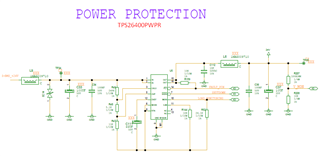

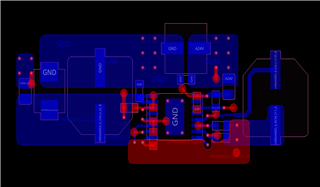

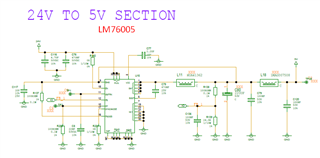

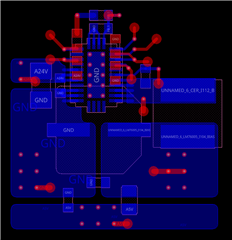

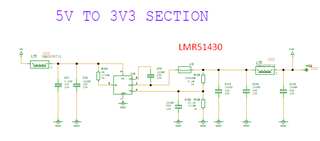

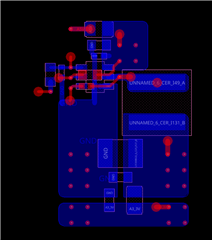

We are designing a custom PCB with 24 V input. we used TPS26400PWPR for power supply protection. LM76005 is used to convert 24 V to 5 V and LMR51430 is used to convert 5 V to 3.3 V. (https://e2e.ti.com/support/power-management-group/power-management/f/power-management-forum/1429731/tps2640-design-validation-for-power-section)

Below are the screenshots of the circuit (schematic and PCB). Please validate the PCB Component placement, layout design and suggest if any modification is required.

The Power requirement for each rail is as follows:

24V rail: 1A max

5V rail: 3.5A

3.3V: 2A

Thanks.