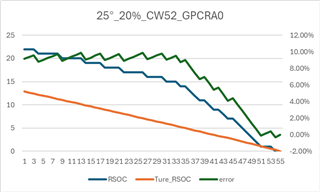

Other Parts Discussed in Thread: BQ40Z50, GPCCHEM, GPCRA0

Tool/software:

hi,

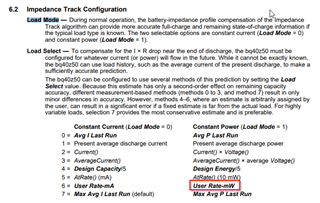

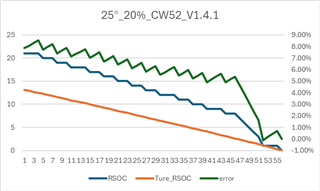

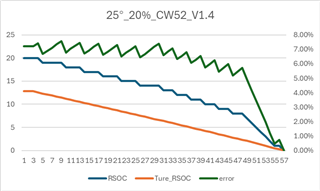

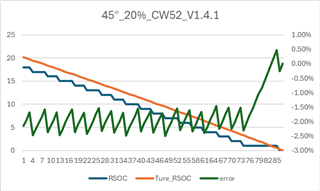

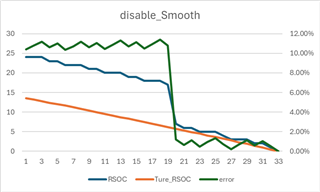

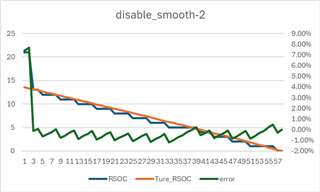

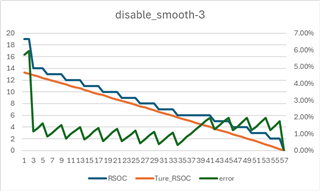

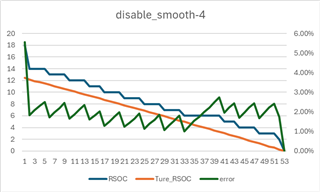

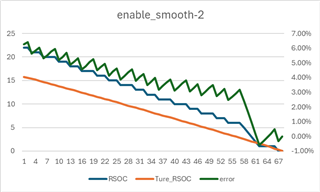

I had a problem using the bq40z50-R4 for drone applications. The battery is a combination of 2S1P, the battery capacity is 1920mAh, and the typical discharge condition is 4C~5C. When the test battery starts discharging on full charge, the accuracy is acceptable, which meets our expectations, but the performance is poor when testing 20% and 50%. Can you help to see how to optimize the relevant parameters to improve the accuracy of non-full charge?

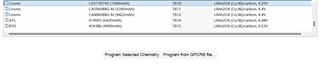

H03A_25deg_20%_CW52_V1.4_20241016.logH03A_0deg_20%_CW60_V1.4_20241017.logH03A_SBP_Gauge_bq40z50-R4_20240823_V1.4.gg.csv