Tool/software:

Hello,

I have a question regarding TPS40210 family's DC-DC ICs.

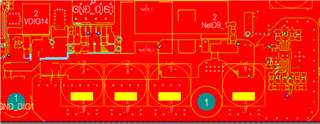

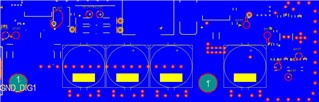

Main question is what's difference between TPS40210 catalog version (TPS40210DGQ) and automotive version (TPS40210QDGQRQ1)? Because previously we were using catalog version and everything was working fine and then we replaced it by automotive version.

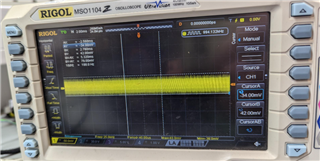

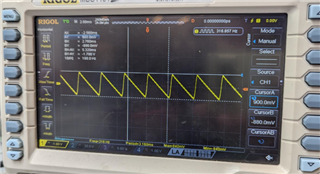

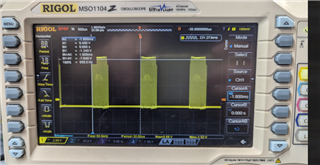

Since we replaced to TPS40210QDGQRQ1 automotive version, the dcdc was unstable under the load, its constantly resetting, similar to overcurrent state but when the load is disconnected the dcdc works normally.

The main problem was that DIS/EN pin was left floating but according the datasheet, the dcdc has 1Mohm pulldown to GND which should be okay for normal operation. We tried to pulldown directly DIS/EN pin to GND and the dcdc started work normally.

So, my question is what's the difference between these two dcdcs and why one's working normally without external pulldown and another requires external to work normal.

Maybe there is some possibilities that the automotive version have more noise and internal 1Mohm pulldown is not enough.

Best regards,