Other Parts Discussed in Thread: TPS55287

Tool/software:

Hi Ti team

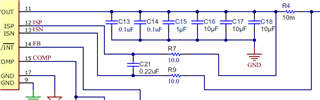

I have designed the circuit based on Webench.

I would like to request your review.

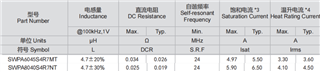

please note that the components I used are in millimeter units.

I have a few questions:

-

Is it necessary to separate AGND? Does AGND apply only to analog components?

- I am using audio, but the distance is over 50mm.

-

Are the BOM components of the EVB in inch units?

-

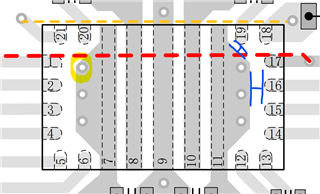

Can I use 0.5mm vias under TPS?

-

For the blue line shown in the picture, how much spacing is recommended?

Thank you for your assistance.

Regards.

Jeong.