Tool/software:

Hello Team,

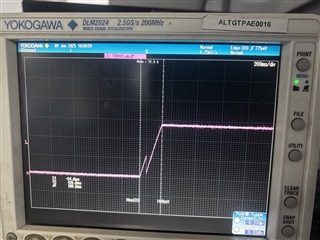

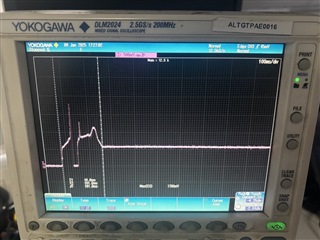

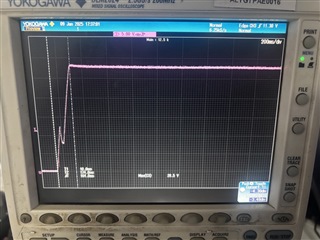

The Buck-Boost converter output becomes unstable after 3 to 6 hours of operation under power-on conditions at 55°C.

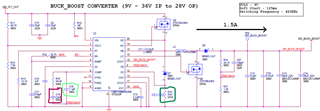

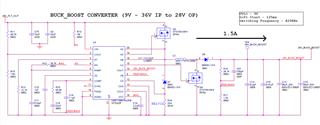

Please see the attached schematic.

The Buck-Boost converter output becomes unstable after 3 to 6 hours of operation at 55°C, even though it continuously restarts.

Please provide solution and suggestions...