Other Parts Discussed in Thread: PMP8740, UCC28950

Tool/software:

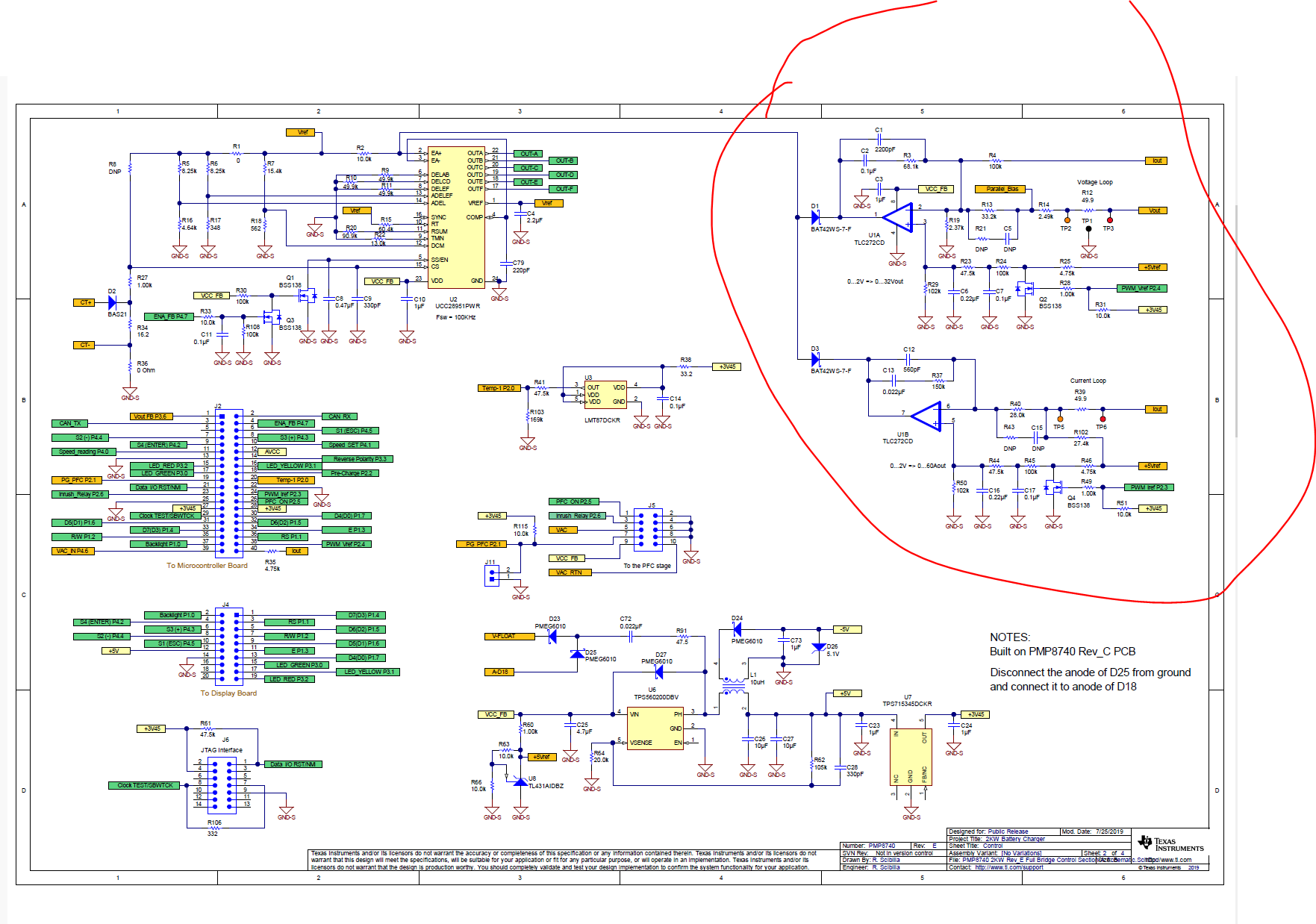

I want to understand the working and design of CC CV control circuit in PMP8740 reference design, but design guide is not available for this reference design. Please, help me to understand the design.