Other Parts Discussed in Thread: BQ25792, GPCCHEM, BQSTUDIO, GPCRA0

Tool/software:

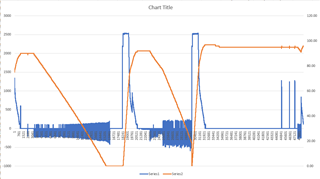

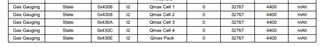

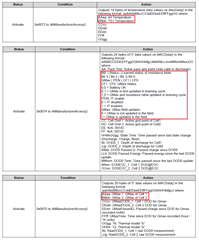

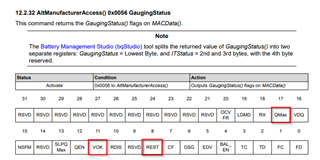

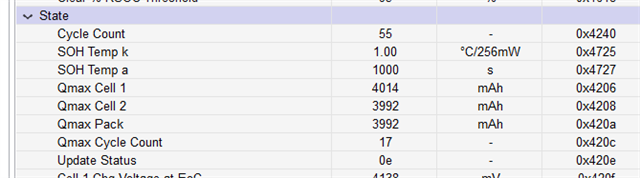

My device has two redundant batteries, each with its own BQ28Z610-R1 and BQ25792 charger. When the battery is fully charged and the charger remains on (supplying system load), sometimes the SoC of one battery will slowly drop (a few % per day) while the battery True remaining energy and battery voltage remain at full charge levels. SoC will drop to zero if we run long enough. This has been happening on a number of devices, but it's a slow process and I've not yet reproduced it on the bench so I can't provide a studio log.

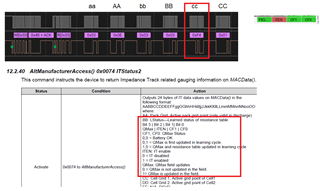

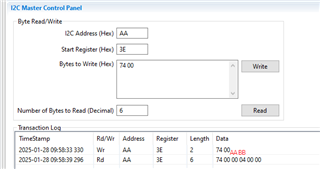

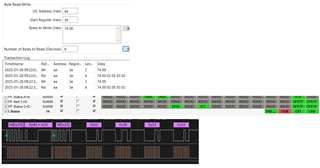

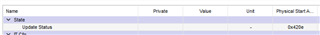

My question is what factors could make SoC deviate completely from True remaining energy? What other values should I log in the device to isolate this?

Batteries are running at normal room temperature, system load is constant but does include a pulsed current load where the battery supplies some of the current briefly (https://e2e.ti.com/support/power-management-group/power-management/f/power-management-forum/1355140/battery-is-charging-when-charge-status-1c-not-charging-000).