Other Parts Discussed in Thread: BQSTUDIO, BQ25720, BQ25756, BQ40Z50, BQ41Z90, BQ25750, EV2400

Tool/software:

Hi Everyone,

I’m seeking an expert advice here on selecting a charger IC as per the below requirements:

I’m working with a 4S Li-ion battery pack with a BMS that includes the BQ40Z50-R2 fuel gauge and a dedicated microcontroller for monitoring. I’m planning to design a charger that utilizes the Advanced Charging Algorithm feature of the fuel gauge.

My current plan:

I will use microcontroller on the charger to poll ChargingCurrent and ChargingVoltage data from the BMS and set the charger output accordingly.

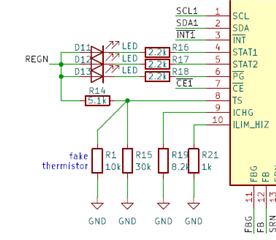

The charger will have two independent output channels, each managed by a dedicated charger IC. Final product will include two charger ICs, with the one microcontroller for monitoring and managing both charger ICs.

For the power supply, I plan to use a market-ready AC-DC module, such as the MEANWELL LOP-300-24, to provide 24V DC to each charger section.

I also have a couple of questions:

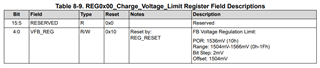

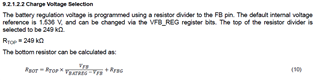

Memory Storage: Do most charger ICs store programmed parameters (e.g., set via BQStudio), or will I need to reprogram these parameters through the MCU after every power cycle?

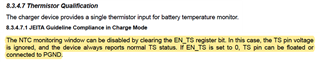

Compatibility with other Batteries: My goal is to make the charger versatile enough to handle other batteries that may not provide ChargingCurrent/ChargingVoltage information or lack SMBus/I2C communication altogether. For that situation, I plan to configure the charger output to a limited current (e.g., 3A).

Please advise on the charger IC selection my choices were BQ25756, BQ25720 and also let me know what to do you think about my approach here.

Thanks