Tool/software:

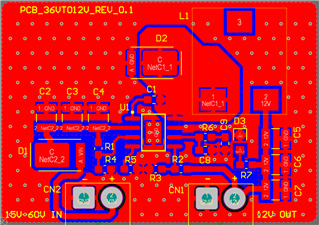

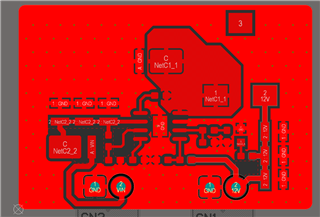

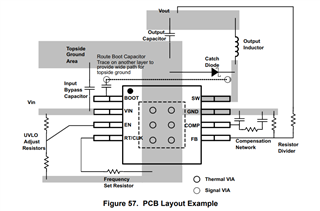

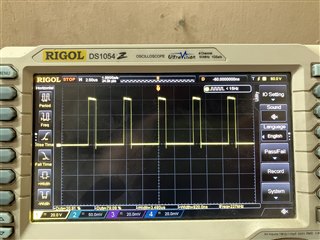

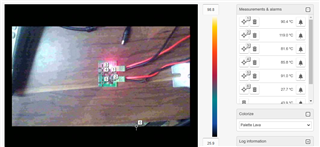

I had designed the buck converter with output voltage of 12V @3.5A. The heating was normal when the input voltage was around 17V to 36V but when applying 60V to the input the chip started heating up rapidly, the load current was about 2.33A @12V during the testing. But no output voltage drop were observed during the testing. The chip temperature rose to about >70 degC. What might be the issue? Is it normal for the chip to rise to such a high temperature during high voltage inputs? Or better thermal management required during high voltage application? I have attached the schematic and layout for your reference.buckconverter.pdf