Tool/software:

Hi All,

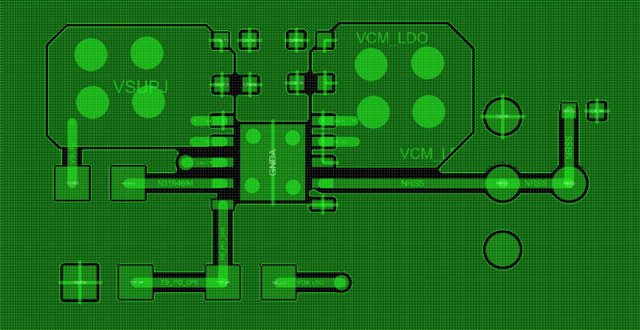

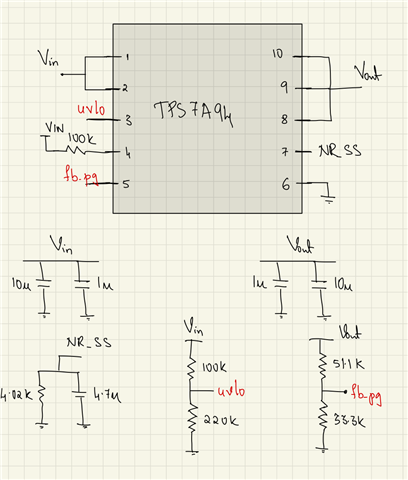

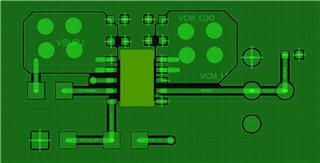

I needed a review for my schematic and layout (images attached). I want the output of the LDO to be 0.6V with a supply voltage of 5V. (As the output voltage is less than 1.2V, the current limit is set to 100% by default). Please let me know if anything needs to change. (I am using a potentiometer for NR/SS resistance control) I am new to PCB design and hence, any help would be greatly appreciated.

Thanks in advance,

Nishanth