Tool/software:

Hello,

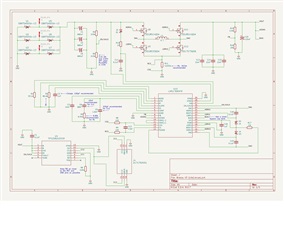

I made a new USB-C charging circuit schematic, which involves an LM5176 as the regulator. The input comes directly from a 3 phase wind turbine, then gets rectified via diode bridge.

Here are the design parameters which I need:

VIN minimum: 2.5V

VIN maximum: 24V

Programmed VOUT Voltage: 5.2V

IOUT Expected Operating Amperage (Per USB-C spec): 1.6A

I built the schematic based off of the recommended schematic provided by the TI WEBENCH Power Designer Tool. However, after designing the circuit, I learned that there is also a calculator tool specifically made for the LM5176.

The Calculator tool doesn't seem to match what the WEBENCH tool provides, and I would like some input from someone else to help me decide what parameters are optimal.

For instance, since this is intended to be powered from a wind turbine, the input voltages will vary by a large amount. The turbine typically outputs anywhere from 0V with no wind, to 20V on the windiest of days. On average, it runs between 3V and 10V. Due to the large variance of input voltages, I'm having a hard time determining an optimal frequency setting.

One other thing to note, the calculator tool is telling me that the output capacitor ESR should be less than 44.8milliohms, but the aluminum output capacitors which WEBENCH recommended all have higher ESR than that.

Finally, I also would like some advise on the compensation design, such as optimal crossover frequency, resistor values, and capacitor values. Once again, WEBENCH suggests values that are different from the calculator tool. I also noticed that the datasheet illustrates Cc1 to be on top of Rc1, but shows the opposite on the schematic in the calculator tool.

In conclusion, here are the parameters I'm not so sure about:

1: Switching Frequency

2: Output Capacitor ESR

3: Compensation Design Component Values (Rc, Cc1, Cc2)

4: Rs value

Below is a copy of the schematic, which was originally designed from the WEBENCH recommendations, with corrections in blue text based off of what the calculator tool showed me.

Below is a copy of the calculator tool with some parameters that I input: