Tool/software:

Hi team,

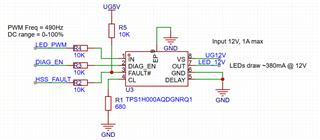

I have designed the following circuit to control a dumb LED strip's (just +12V and GND) power and brightness. The EN pin will be PWM'd in order to control brightness, and the switching frequency for that will be 490Hz.

It will be getting a regulated 12V input at VS and it can supply 1A maximum. The LED strip will draw about 380mA maximum. Can you check the schematic to make sure it is designed correctly, will the supplied power be enough, and if I can use my desired PWM control scheme successfully on it?

Thank you in advance!