Other Parts Discussed in Thread: TPS25751, BQ25730, TPS55288, , TPS65987, , TPS25730

Tool/software:

Hello,

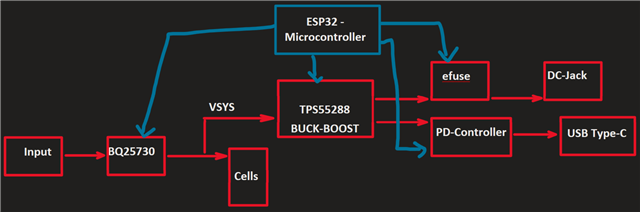

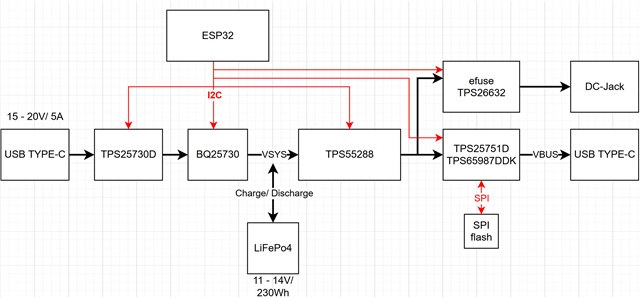

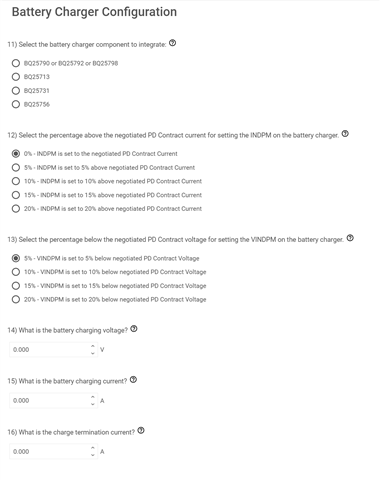

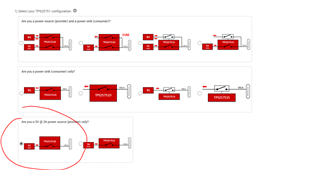

I am currently working on a power bank design that utilizes the TPS65987D as a power source, capable of delivering up to 100W. My design features two outputs: a USB PD source as the primary output and a DC-Jack as the secondary output. To ensure only one output is active at a time, an eFuse is used to control the on/off switching of the DC-Jack output.

To guarantee that VSAFE5V is always available on the USB Type-C port—and to prevent any unintended voltage from being applied due to a prior setting from the DC-Jack output—I am looking for a solution.

Is it possible to achieve this by using a microcontroller or through manual control to switch the PD controller on/off or place it into a sleep mode until the VSAFE5V is guaranteed at PPHV1,2?

Thank you!