Tool/software:

We noticed that the powerpad/paddle are recessed into the mold compound by about 10-30 microns on some of the parts we received.

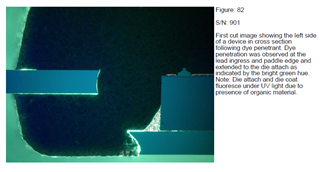

On the same parts we observed some dye penetration that made it to the die attach. Please see the image below.

Is there a link between paddle recession and the mold compound? Did the mold compound prevent it from creating a good seal which led to dye penetration? Is the recessed paddle a issue for part performance?