Other Parts Discussed in Thread: BQ76940, BQ76200, BQ25756

Tool/software:

Hello,

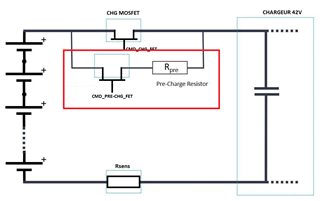

I'm working on a BMS design (BQ76940 & BQ78350-R1A & BQ76200) for an e-bike application and need advice on an efficient precharge circuit. The simple design with a MOSFET and resistor in series for precharge is causing high power dissipation and requires a high power rating for the resistor.

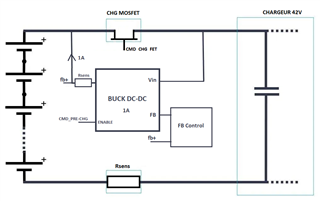

My battery configuration is 10S4P, and the recommended precharge current is 303mA per cell, which means 1.2A for the 4 cells in parallel.

Additionally, the indicator LED on our charger needs a consumption current of more than 600mA to switch from green to red.

Moreover, the current with the simple precharge circuit decreases during charging (from battery = 25V to 30V) and takes more time to charge in precharge mode.

I'm looking for a design recommendation that uses a current generator like a DC-DC converter with Rsense feedback. The goal is to minimize space with SMD components on the PCB and reduce power dissipation in the precharge circuit.

Any suggestions or design ideas would be greatly appreciated!

Best regard,

Ahmed