Tool/software:

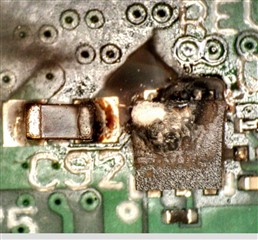

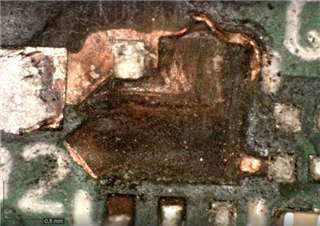

I am seeing a failure mode on the enable pin of the TPS22810 melting and the TPS22810 packaging melting during normal operation with Vin=12V. The datasheet specifically calls out that the enable can be driven by a 1.8V, 3.3V or 5V GPIO on page 15, but the recommended operating conditions for Ven Min/Max are 0-18V. In our system we tie the enable directly to Vin and Vin=8-15V. In the failure mode the system is running at 12V in normal steady state condition and the TPS22810 spontaneously fries. The steady state draw of the system is 250mA current. Can you verify that the enable pin can handle being shorted to the VIN with 12V-15V?