Other Parts Discussed in Thread: , PMP40801

Tool/software:

Hi,

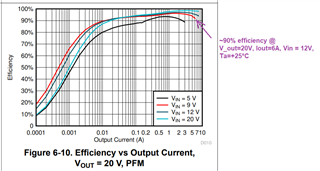

according to the TPS55288EVM-045 Evaluation Module (slvubo4b) the input voltage must be 12V or higher if 100W (20V/5A) is going to be tested at output.

Could you tell us which component is bottleneck for Vin operation below 12V?

Webench allows simulation with these parameters, therefore I am asking why the Vin must be higher than 12V in the eval board.

Also, Webench doesn't allow simulation with Vout higher than 20V .Is this correct or I am doing something wrong in simulation?

Datasheet says Voutmax=22V and moreover there is a feature cable voltage drop compensation that can go +0,75V above target voltage, if I've understood that correctly.

Could you please compare results between Webench and excel calculation sheet for the IC Pd parameter when it works in boost mode, Vin is the lowest?

Should they match?

BR

Josko