Other Parts Discussed in Thread: BQ24074

Tool/software:

Hello,

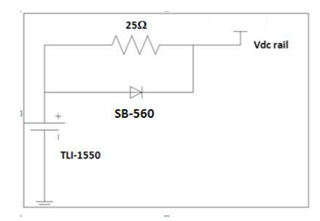

I would like to use the BQ25185 in an intrinsically safe design to be used in hazardous environments. To do so, I am required to add a 25Ω current limiting resistor in parallel with a diode right at the battery prior to connecting to the BQ25185 chip. The current limiting resistor is for limiting charging current and the diode is forward biased in the discharge path. See picture below.

How will these additional components affect the charging ability of the BQ25185 and the ability to discharge from the battery? Is there something I can do to ILIM/VSET and ISET to allow me to use these protection components?

Additionally, I have to protect against multiple faults on the BQ25185 chip, including shorts to all pins. For example, if VIN (5V in my case) was shorted to BAT, would the chip automatically enter fault condition if the battery voltage was 5V? Or do I need to add more protections against this externally from the chip?

Thanks,

Gabe