Tool/software:

Hi team,

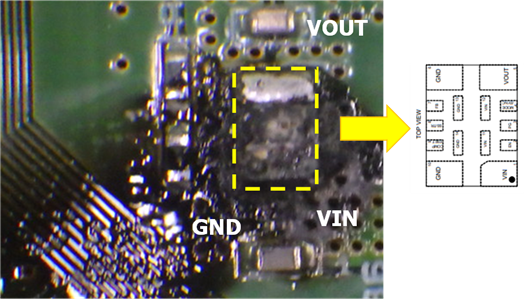

Our customer using this device and tested on the board whitch they designed.

When the test, one device was failure by burnout. From the failure occure only one case, low frequency of occurrence, we think this burnout is from damage during implementation and overvoltage mainly.

The customer want to know about other causes and information of similar failure cases using this device.

Do you have any information of similar failure cases on this device using?

Best regards,

teritama