Tool/software:

Hi!

I'm using two TPS929160 on a new board to drive 32 LEDs (1 per channel). The LEDs have a nominal forward voltage of 3,1V @ 120mA but I don't need to use them at their full power, 100mA would be OK!

Everything seems to be working just fine, I imported and adapted the EVM code to work on a PIC18F and I can run the different patterns that are on the original EVM code.

But I'm having a problem with the maximum driven current. The maximum I had until now was around 20mA per channel.

Even if I drive only one LED that is the maximum I get. The LED attached to ERR pin keeps turned off everytime (but it works, I've seen it in the past).

I already tried using different voltages (12V and 5V) on Vsupply and Vbat, nothing different besides heat dissipation.

I changed the FSx configuration and got the same result.

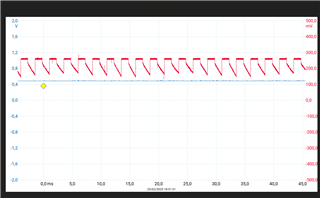

I'm using R(ref) = 6K32 and getting V(ref) = 1,235V. VLDO is 5V.

Do you have other ideas that I may look for?

I'm leaving in attach a piece of code that I am using and that is basically imported from the EVM code.

Thanks in advance for your attention.

BR

// Calculate and store the CRC of data from 0x00 to 0xFF

crcInitial();

// When CAN is not used, the read offset is always 0. When CAN is used, it depends on the number of transmitted bytes.

if(CAN_USED == FALSE) {

read_offset = 0;

}

// Unlock device

clearLockAll(BROADCAST);

// Clear POR, FAULT for device

setClr(BROADCAST, CLRFAULT | CLRPOR);

// Check if ACKEN is set

for(dev_idx = 0; dev_idx < DEVICE_CNT; dev_idx++) {

FlexRead(device_address[dev_idx], FLEXWIRE0, DATA_LENGTH__1, TRUE);

if(ledRcvBuffer[read_offset] & ACKEN_1) {

ackEnabled[device_address[dev_idx]] = TRUE;

}

else {

ackEnabled[device_address[dev_idx]] = FALSE;

}

}

// ***Disable all channels for device - this is reset value of register, but ensure for restart of program

disableAllCh(BROADCAST);

// Set PWMFREQ = 2000Hz

// Can set PWM frequency as broadcast which will overwrite all other settings in same register

setPWMfreq(BROADCAST, PWMFREQ__2K0);

// Need to set REFRANGE per device to retain existing setting - PWM frequency and REFRANGE are for TPS92912x in the same register

// Set REFRANGE = 512

for(dev_idx = 0; dev_idx < DEVICE_CNT; dev_idx++) {

setRefRange(device_address[dev_idx], REFRANGE__512);

}

//***Set DC for all Channels - actually this is the reset value in EEPROM

regValue[0] = IOUT__MAX;

setIOUTAllCh(BROADCAST, ®Value[0], TRUE);

//***Set PWMOUT for all Channels - PWM high is reset value in EEPROM and PWM low is reset from register

regValue[0] = PWM__1;

setPWMAllCh(BROADCAST, ®Value[0], TRUE);

setPWMhighAllCh(BROADCAST, ®Value[0], TRUE);

// Set Single-LED-Short threshold and Low Supply Threshold - Settings are for EVMs

setSLSth(BROADCAST, SLSTH0__2V50, 0);

setSLSth(BROADCAST, SLSTH1__2V50, 1);

// Need to set SLSEN and LowSupplyTh per device to retain existing setting - REFRANGE is for TPS929160/240 in the same register

for(dev_idx = 0; dev_idx < DEVICE_CNT; dev_idx++) {

setLowSupplyTh(device_address[dev_idx], LOWSUPTH__4V);

enableSLS(device_address[dev_idx]);

}

// Clear FAULT for device because low supply threshold was just set

setClr(BROADCAST, CLRFAULT);

// Enable diagnostics for all channels - actually this is the reset value in EEPROM

enableDiagAllCh(BROADCAST);

//Assign LED Drivers to the correct LED according to the model and color of the LEDs

if(model == MODEL_REAR)

{

blinker_dev_idx = LED_DRIVER_1_IDX;

otherFunc_dev_idx = LED_DRIVER_2_IDX;

blinker_limit = BLINKER_NLED_REAR-1;

}

else //if MODEL_HEAD

{

blinker_dev_idx = LED_DRIVER_2_IDX;

otherFunc_dev_idx = LED_DRIVER_1_IDX;

blinker_limit = BLINKER_NLED_HEAD-1;

}

//Turn off all LEDs

enableAllCh(device_address[blinker_dev_idx]);

for(ch_idx = 15; ch_idx >= 0; ch_idx--)

{

regValue[0] = PWM__0;

setPWMoneCh(device_address[blinker_dev_idx], regValue, device_LED_idx[ch_idx]);

}

//Enabling one LED only

regValue[0] = PWM__1;

setPWMoneCh(device_address[blinker_dev_idx], regValue, 8);