Other Parts Discussed in Thread: BQSTUDIO

Tool/software:

I completed the learning cycle using the LFP battery.

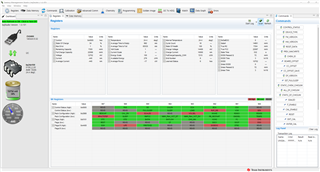

I created a golden image, created an srec file, and downloaded it to another board and am using it.

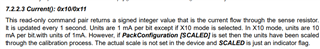

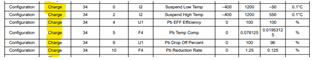

During use, the battery power was disconnected, so I downloaded the golden image again and calibrated the CC Offset, current, voltage, etc.

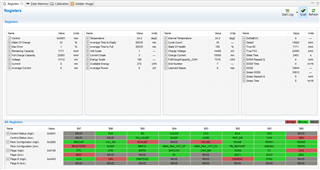

From here, the current is different from the actual measured value, and the CHG bit of the Flags is always high.

The actual current consumption measured with a current meter is 4A, but it is less than 1A in Bqstudio. What is the problem that the CHG bit is always high when the power is connected only to the BQ34Z100???