Other Parts Discussed in Thread: GPCCHEM, BQSTUDIO

Tool/software:

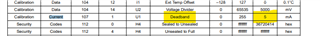

We have a problem with calibrating the BQ34100-G1 fuel gauge IC in our product.

Basically, the the fuel gauge reports 5mA (5mA resolution) on some units when no current is flowing to/from the battery. This is the most crucial part of the calibration that our product requires. Failure to read 0mA results in a failed unit.

We have submitted our data to the TI server and are using the Golden Image file that was supplied. This is programmed into the BQ34Z100-G1 by the product's processor.

Is there an algorithm or code that our processor can run to calibrate the current sensing and give us a 0mA reading for no current?