Other Parts Discussed in Thread: TPS61023, , BQ25896, BQ25622, BQ25890, BQ25628E, TPS631000

Tool/software:

Hello.

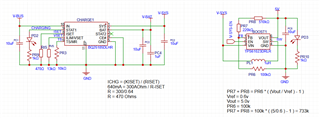

I have a BQ25185 and TPS61023 circuit to charge a large lipo (3700mAh) at about 640mA, but the battery voltage only climbed about 10% (3.79v to 3.89v) after about 3 hours.

I have tried a range of 7v to 15v input, and the results have not changed. 12v would be close to the actual input for our use case. The controller that is powered by the battery is only using about 60mA, and it seems like I'm only getting about 130mA of current into the battery, or about 20% of the expected charge current. The actual resistor value for Vset is reading as about 12.5k instead of 13k. These are what led me to belief that it is stuck in pre-charge. I will attempt to replace the resistor, but advice is greatly appreciated in general.

The circuit I am using is the following. Vsys flows into the TPS61023 boost converter to guarantee more than 3.3v for the controller regulator while the charging input is removed. Any advice on what might be wrong here, or a single chip recommendation that can consolidate this circuit, would be hugely appreciated. Thank you.

I also seem to be getting 5.7v out of the boost chip instead of 5.0v, but that seems like a separate issue with my resistor quality.