Other Parts Discussed in Thread: LM5180, , LM20242

Tool/software:

Hello TI-experts,

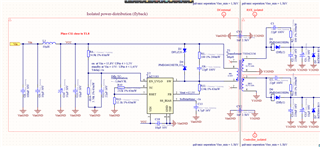

I am designing a dual output power supply with following requierements:

Vin: 16...32VDC

Vout1, Iout1: isolated, 12.1VDC, 300mA max

Vout2, Iout2: isolated, 12,1VDC, 300mA max

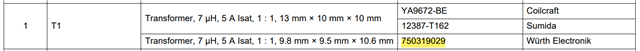

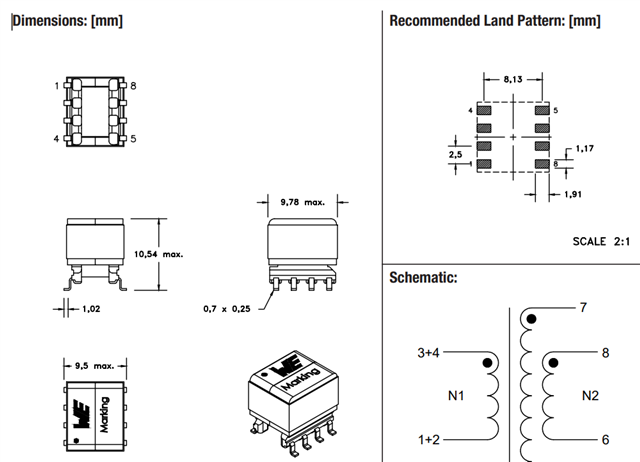

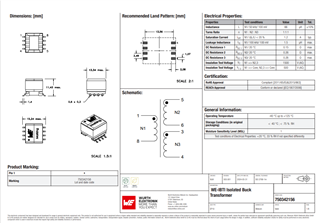

Isolation up to 1,5kV. I will use wuerth WE-IBTI 750342156 see schematics:  datasheet T1 and its connections:

datasheet T1 and its connections:

Now with satiesfied interal review, I started routing the board. Since I have a very limited space I am struggeling with the following details:

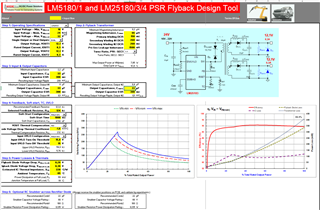

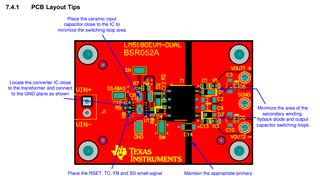

Placing LM25183 and T1 on top close to each other similar to the eval-board of LM5180 (part of this switcher series) link this

I am struggeling with connecting the switching node pin 1 of the LM close to T1 pin 1 and in the same time with connecting pin 3 of the LM to T1 pin 8. They have to cross each other, which needs to use a second layer to do so: